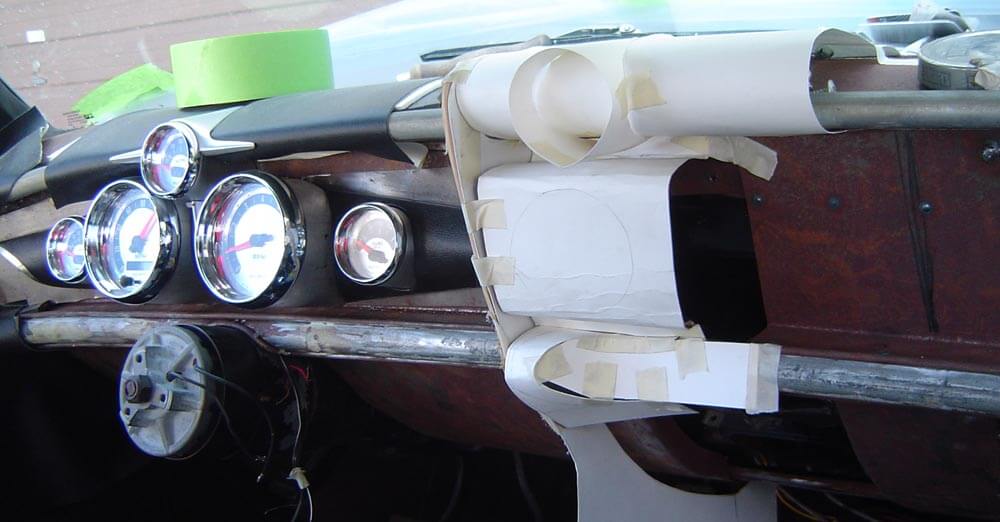

This 1968 Camaro received a complete interior redesign. The dash was removed and we started from scratch– even redesigning the dash cap. The customer specified a predominately black interior and we decided on red, used sparingly, to make for a nice accent color. All the red moldings you see are made from 3/16″ brass, sanded to fit and align, drilled and tapped for 4×40 studs to facilitate installation, and then primed and painted in a UV stable red. The customer requested a center console and rather than just design a stand alone console we designed a two tier free floating unit. The console was designed to house the power window switches, as well as relocate the wiper switch and headlight switch. Everything you see here, every trim piece, every detail molding was designed and hand built. Only the door handles are OEM. Only the A/C vents and an A/C controls are aftermarket supplied. Vinyl and other pertinent materials are used to set tolerances and gaps necessary during the early phase of design so as to insure perfect fitment when final assembled. Blue LED lighting features are used behind switches and controls for ease of operation during nighttime driving.

Curves and sweeps are carefully calculated as well as keeping an exacting eye on gaps by constantly checking with the upholstery fabric to be used in the final finishing process. Armrests are several pieces hand made from aluminum. They are shaped and fitted by removal and reinstallation as many as 20 or 30 times both to assure exacting fitment as well as location and securing the hidden fasteners. Hand made speaker cover panels are already covered in vinyl (temporarily) to keep an eye on gap, fit and alignment throughout the design process.